A company that always accommodates customers' needs,

and responds with creativity and ingenuity.

Our "Monozukuri" strategy is

not based on commoditized methods.

Our method is "Digital Monozukuri",

which focuses on things that everyone could do,

but no one is actually doing.

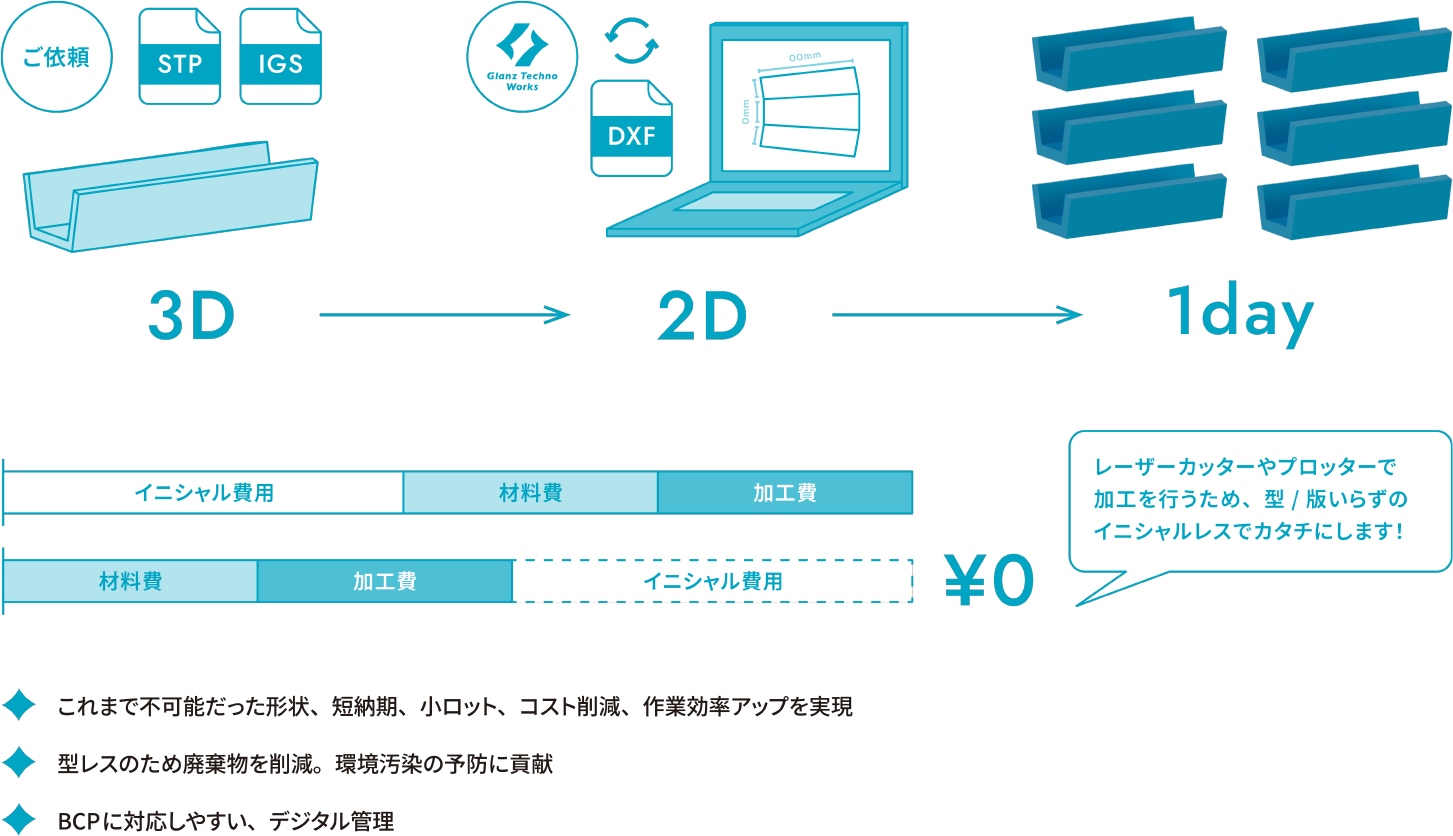

Smart waysMore freedom in manufacturing

with initial-less processing.

Our proposed "initial-less processing (3-2-1-0processing)" is a processing program that reduces both costs and time.

From the 3D data received, we can generate 2D drawings in as little as 1 day without the need for molds or plates.

No initial costs (such as mold or plate fees), no additional costs for shape changes, and no maintenance or storage fees - it's initial-less (0yen).

We propose to "make manufacturing more creative with digital 'Monozukuri'!".

Processing Examples

We offer a wide variety of processing with high precision.

Instead of simply processing a single material, we achieve products made from multiple materials by devising innovative ways when creating data.

-

Half-cut Processed Products

-

Multi-step Processed Products

-

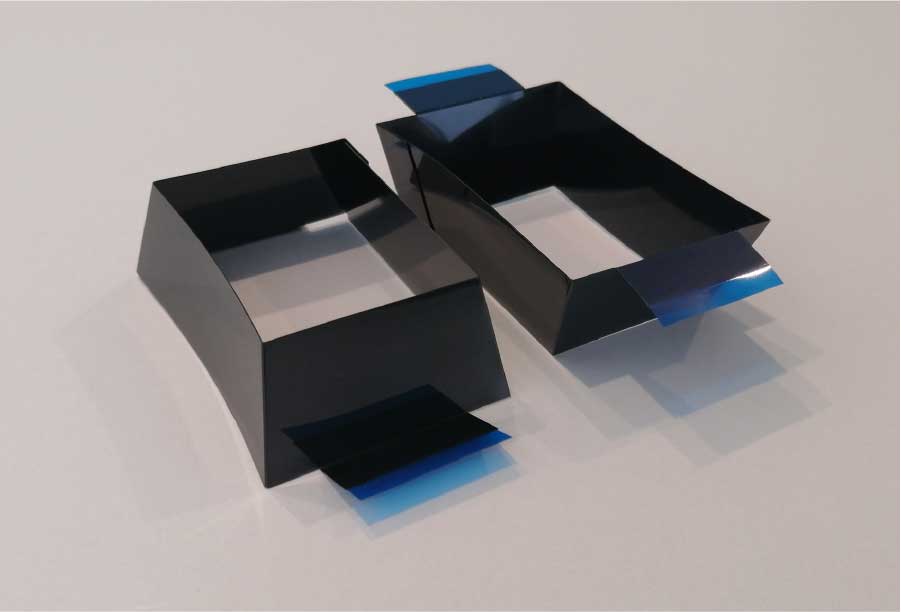

3-D Processing and Bending Processed Products

-

Engraved Products

-

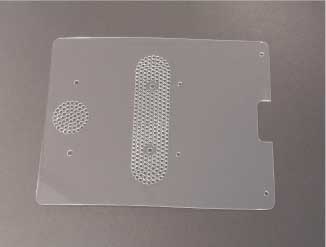

Printing Process Parts / Assembly Jig

-

Difficult-to-Process Products

-

Precision Machined Parts

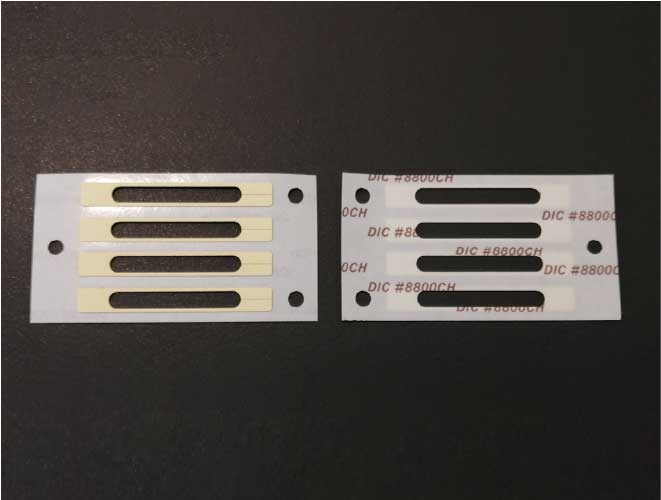

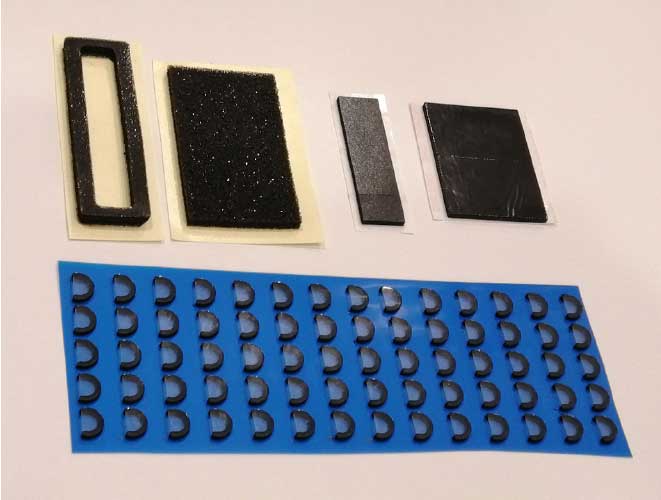

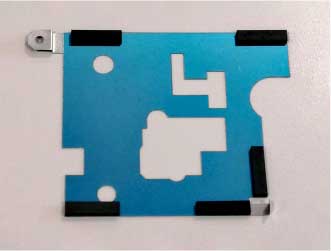

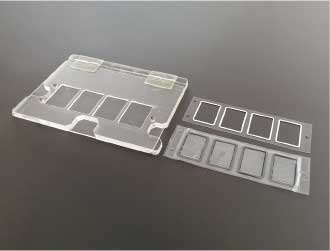

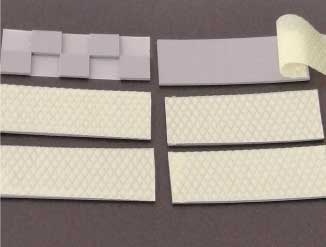

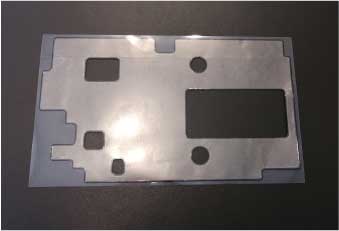

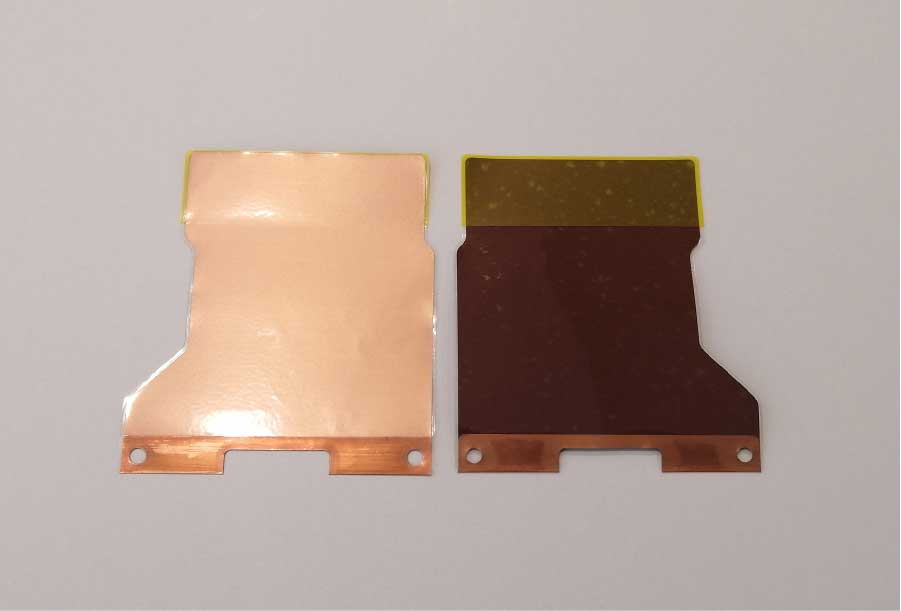

Half-cut Processed Products

We finish metal parts that have been bent by partially attaching insulation sheets.

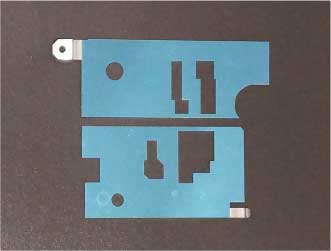

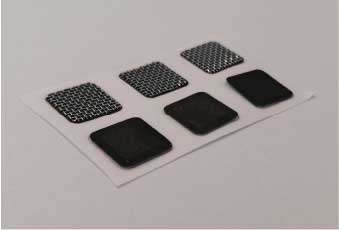

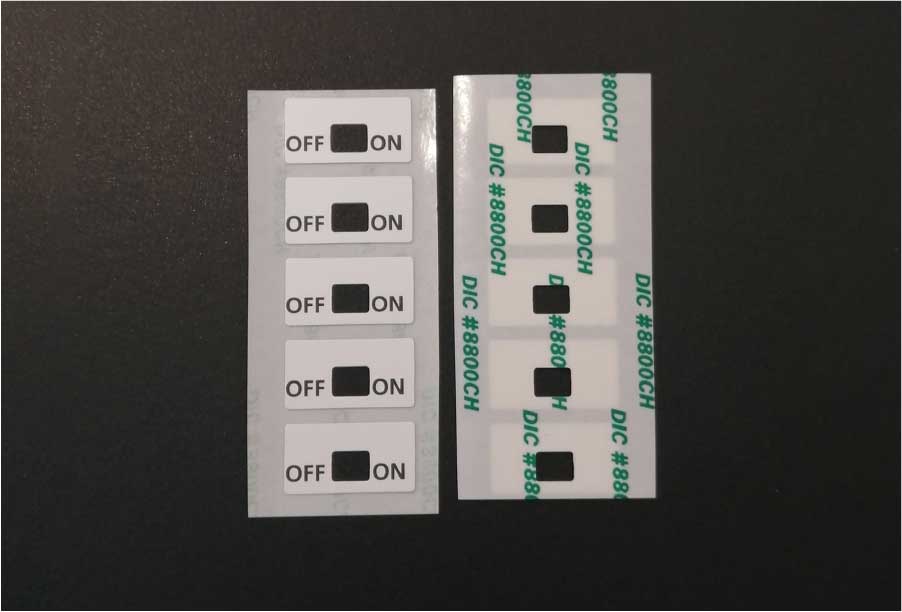

Multi-step Processed Products

It is also possible to process combinations of multiple materials with different properties.

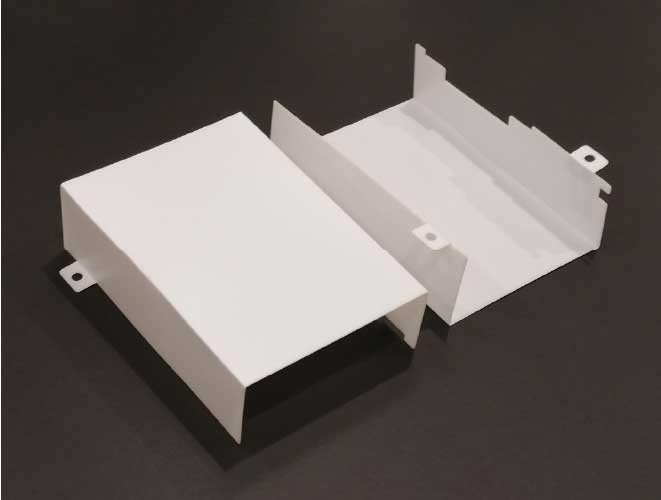

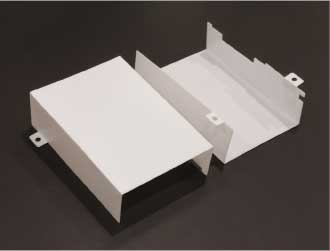

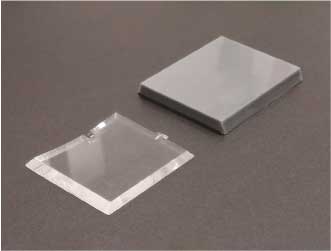

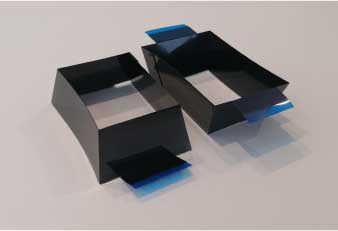

3-D Processing and Bending Processed Products

It is also possible to perform bending with minimal spring-back.

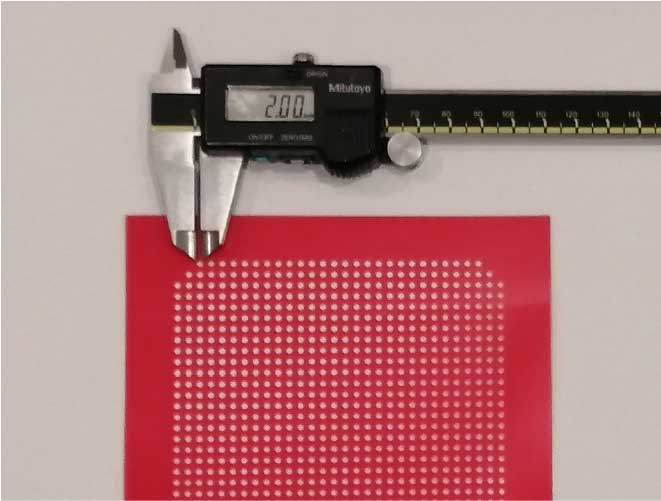

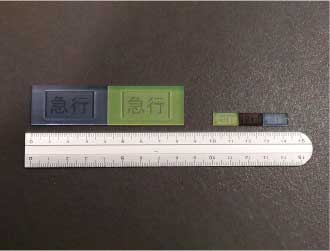

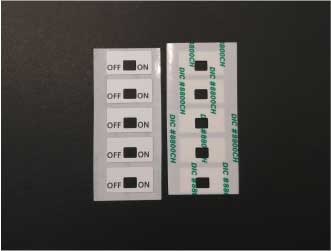

Engraved Products

Engraving on the surface of the material is also possible.

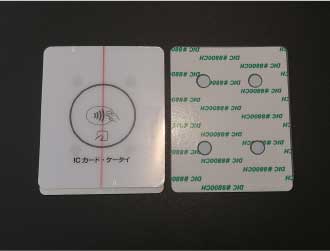

Printing Process Parts / Assembly Jig

Printing Process Parts / Assembly Jig

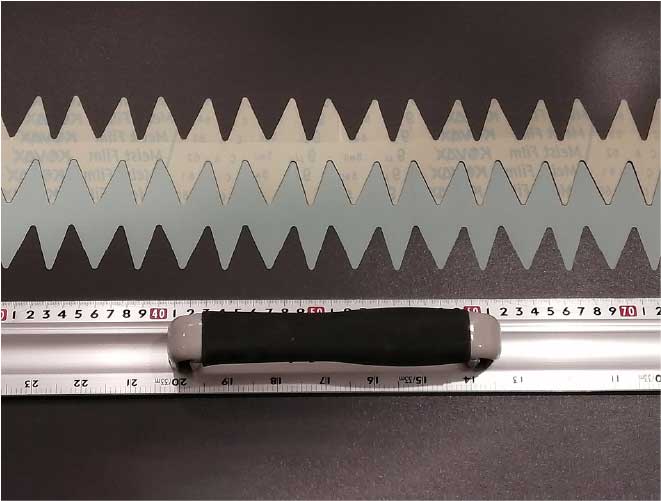

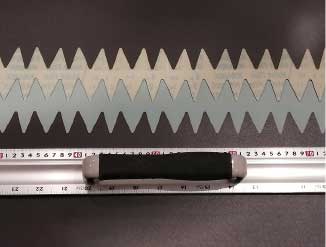

Difficult-to-Process Products

We are working on long objects and Difficult-to-process materials.

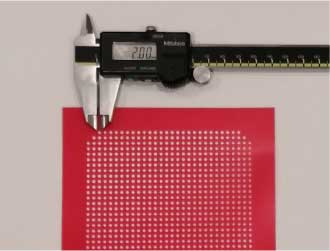

Precision Machined Parts

We can create small-batch, multi-variety precision parts by utilizing the capabilities of our processing machines.

Services

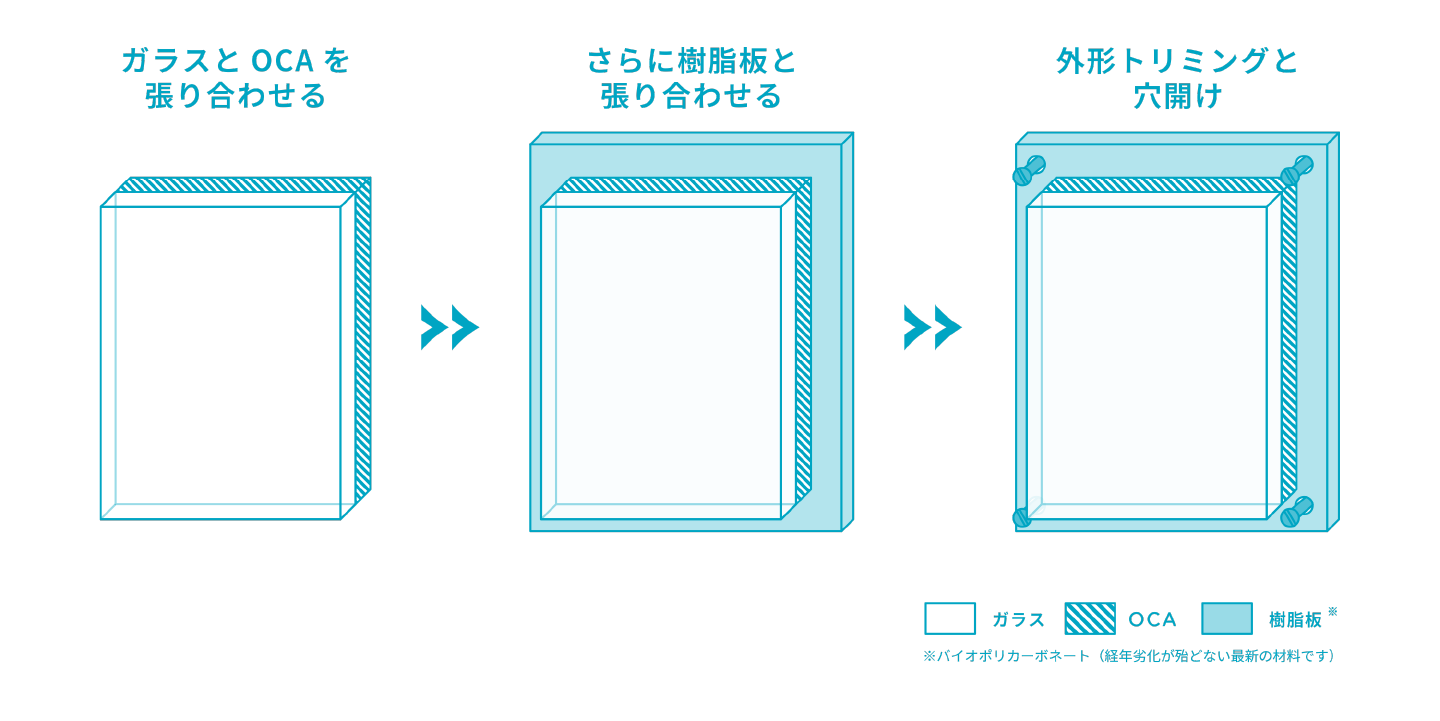

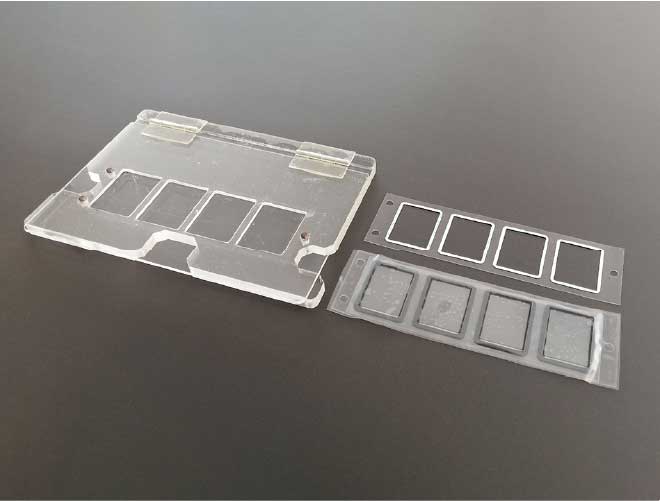

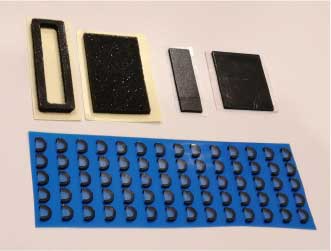

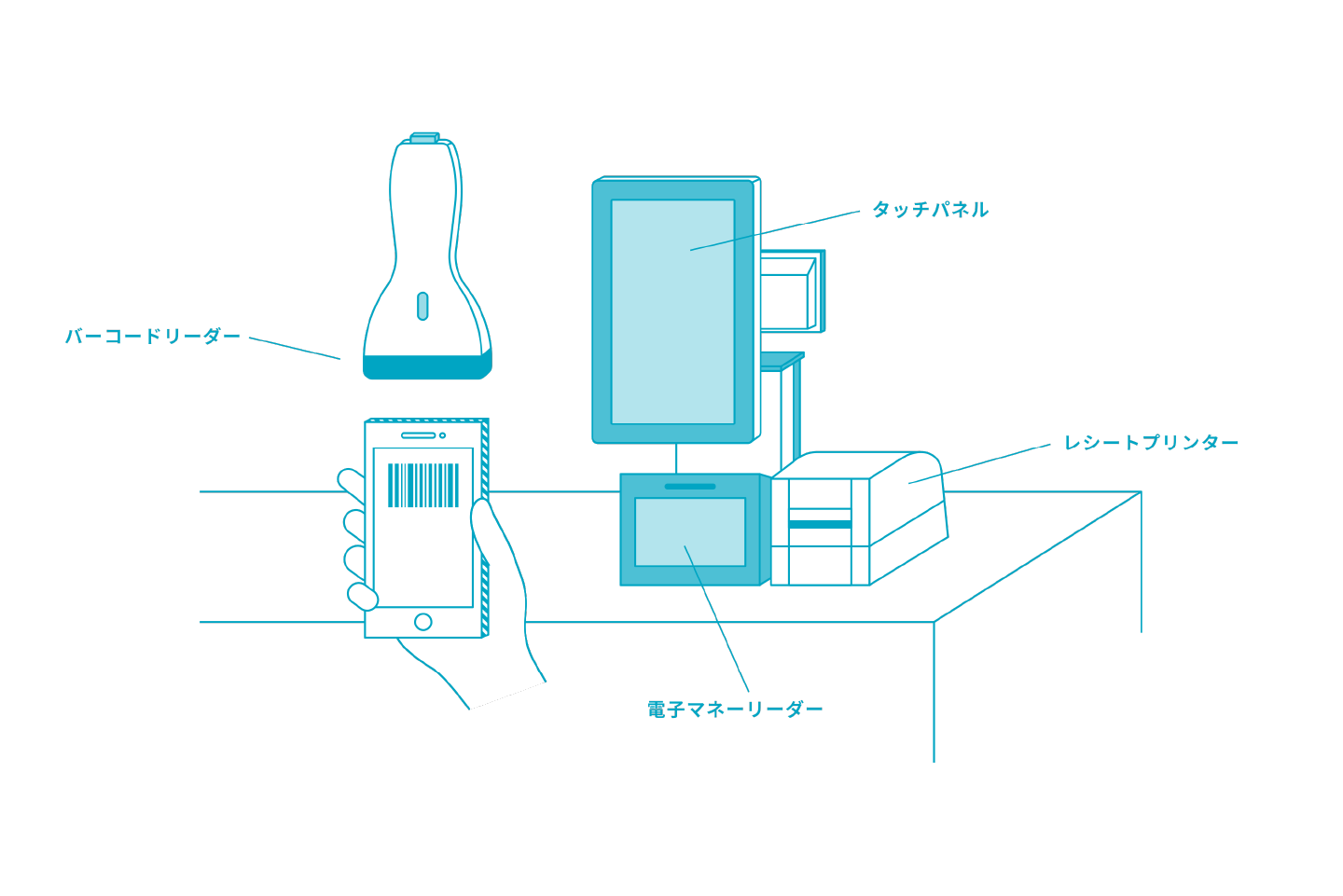

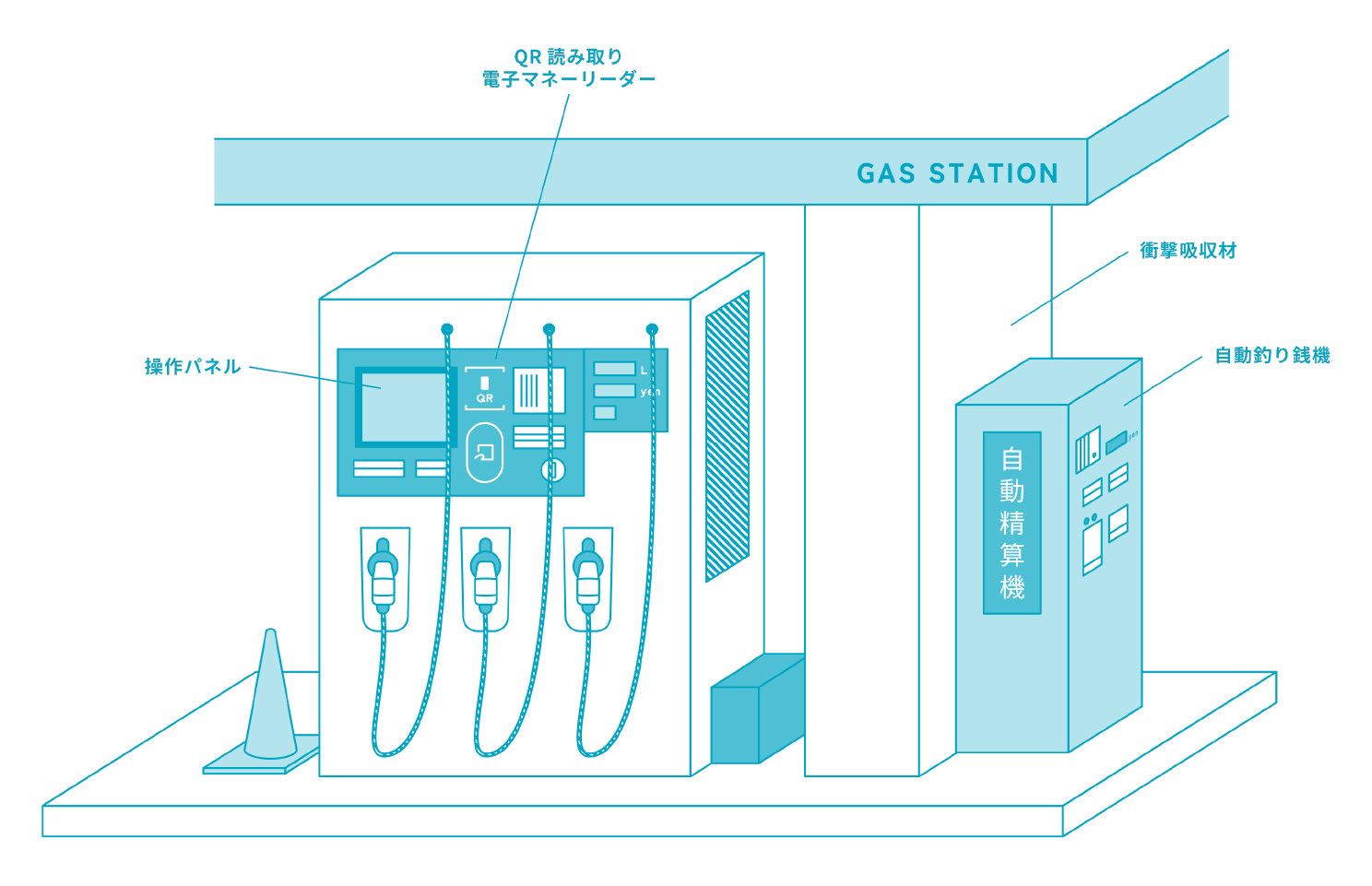

Creating Functional Parts

We complete functional parts made from a combination of multiple materials with high precision, directly from 3D CAD data, and without any initial costs. We can also handle processing of irregular shapes through a multi-step process.

Creating Printed Processed Products

Inkjet printing is used for initial-less finishing. Lamination and bending of printed products and double-sided tapes are also available.

Creating 3-D Products

We can achieve a clean finish even on bent parts with spring-back, as well as on delicate, easily fraying fabric materials.

-

Development Sample

[Railroads & Transportation] Development of materials for signage, soundproofing walls, sound insulation walls, etc.

[Stations & Public Facilities] Development of materials for walls and partitions

[Various Industrial Products] Development of parts

and materials for ATM, cashless devices, drones, and security devices -

Examples of Products We Offer

- Ultra-low Reflection Film (MOSMITE™)

- Bio-Polycarbonate

List of Clients

- INOAC Group

- NAGASE ABRASIVE MATERIALS

- Mitsubishi Chemical Group

- IWATSU Electric Group

- NISSAN TRADING

- Meiko Group

- NEC Group

- Laird Technologies Japan

- MEIWA CORPORATION

- SAXA Group

- HERZOG JAPAN

- Daiwa Lease

- Sansuisha

- Panasonic Group

- Japan Tobacco

- TAKAMISAWA CYBERNETICS

- Ministry of Defense / Japan Ground Self-Defense Force

- RYODEN

- Japan Railway Construction, Transport and Technology Agency (JRTT)

- Mipox

- Watanabe Electric Group

and 30 other companies (titles omitted)

About Us

Introduction video

|

Corporate Name |

Glanz Techno Works Corp. |

|---|---|

|

Registration Number |

Qualified Invoice Issuer Registration Number T3-0124-0103-5372 |

|

President |

Tetsuo Miyamoto |

|

Established |

May 30, 2019 |

|

Capital |

10 million yen |

|

Location |

1-30-2 Higashi Izumi, Komae-shi, Tokyo 201-0014 |

|

Number of employees |

8 |

|

Phone |

+81-3-5761-8030 |

|

FAX |

+81-3-5761-8856 |

Inquiry Form

Privacy Policy

At our company, we recognize that personal information of customers and all other parties involved in our business activities should be handled appropriately and carefully under the Act on the Protection of Personal Information and the principle of respect for individual privacy. Based on the understanding that this is not only for compliance with laws and regulations, but also being closely related to the rights and interests of individuals, we pledge the following in connection with handing personal information.

We will comply with the Act on the Protection of Personal Information, guidelines in the economic and industrial field regarding the Act, and other related laws and regulations. We will also handle personal information appropriately in accordance with generally accepted practices.

We will clarify rules and regulations regarding the handling of personal information and ensure that all employees and other related persons comply with them. We also request our business partners etc. to handle personal information appropriately.

In handling personal information, we shall, in principle, specify a retention period within the scope necessary for the purpose of use, and delete personal information after the retention period has elapsed or the purpose of use has been achieved, except in cases where exceptions are permitted by law.

We will take necessary measures to prevent leakage, loss, falsification, etc. of personal information and manage it properly.

Requests by a person for disclosure, correction, deletion, or suspension of use of personal information in our possession will be accepted at the designated contact point and will be handled conscientiously.

Creating Functional Parts

Creating Functional Parts